With the rapid growth of the palm oil industry, large volumes of empty fruit bunches (EFB) are generated every year. Traditionally, EFB has been treated as agricultural waste, creating disposal challenges and environmental pressure. Today, however, advanced pelletizing technology allows EFB to be converted into clean, renewable biomass fuel. The EFB pellet machine plays a key role in this transformation, helping producers unlock new economic value from palm residues.

Understanding EFB and Its Pelletizing Potential

Empty fruit bunches are fibrous, lightweight, and rich in lignocellulosic material. These characteristics make EFB suitable for pellet production, but they also present processing challenges such as high moisture content and low bulk density. To overcome these issues, a dedicated pelletizing system is required, combining drying, size reduction, and high-pressure compression.

When processed correctly, EFB pellets offer stable calorific value, easy storage, and convenient transportation. They are widely used as industrial boiler fuel, power plant feedstock, and co-firing material in biomass energy projects.

(Related Post: https://biomasspelletizer.com/efb-pellet-machine/)

Core Components of an EFB Pellet Production Line

A complete EFB pellet line is more than just a single machine. It is an integrated system designed to ensure efficiency, consistency, and durability.

- Pre-processing section

Raw EFB is first shredded and crushed to achieve uniform fiber size. This step improves drying efficiency and ensures smooth pelletizing. - Drying system

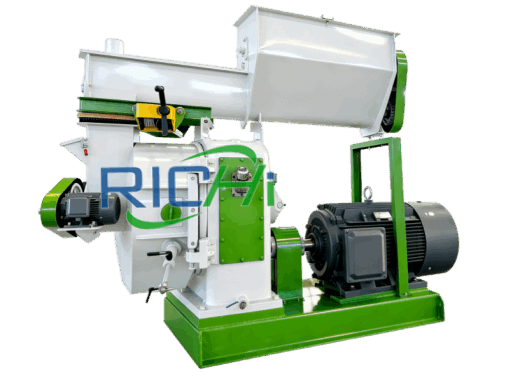

Moisture reduction is critical. EFB typically requires drying to an optimal level before entering the pelletizing stage. - Pelletizing unit

At the heart of the line is the pellet mill, which compresses EFB fibers into dense, cylindrical pellets using high pressure and friction-generated heat. - Cooling and screening

Fresh pellets are cooled to enhance hardness and screened to remove fines before packaging or storage.

This integrated approach forms a reliable industrial EFB pellet plant solution for medium- and large-scale biomass producers.

Why Choose an EFB Pellet Machine for Industrial Use

Investing in specialized pellet equipment offers several long-term advantages:

- Improved waste utilization: Converts palm waste into a sellable energy product

- Lower fuel costs: Reduces reliance on fossil fuels in industrial boilers

- Stable output quality: Uniform pellet size and density for consistent combustion

- Scalability: Suitable for small plants upgrading to full industrial operations

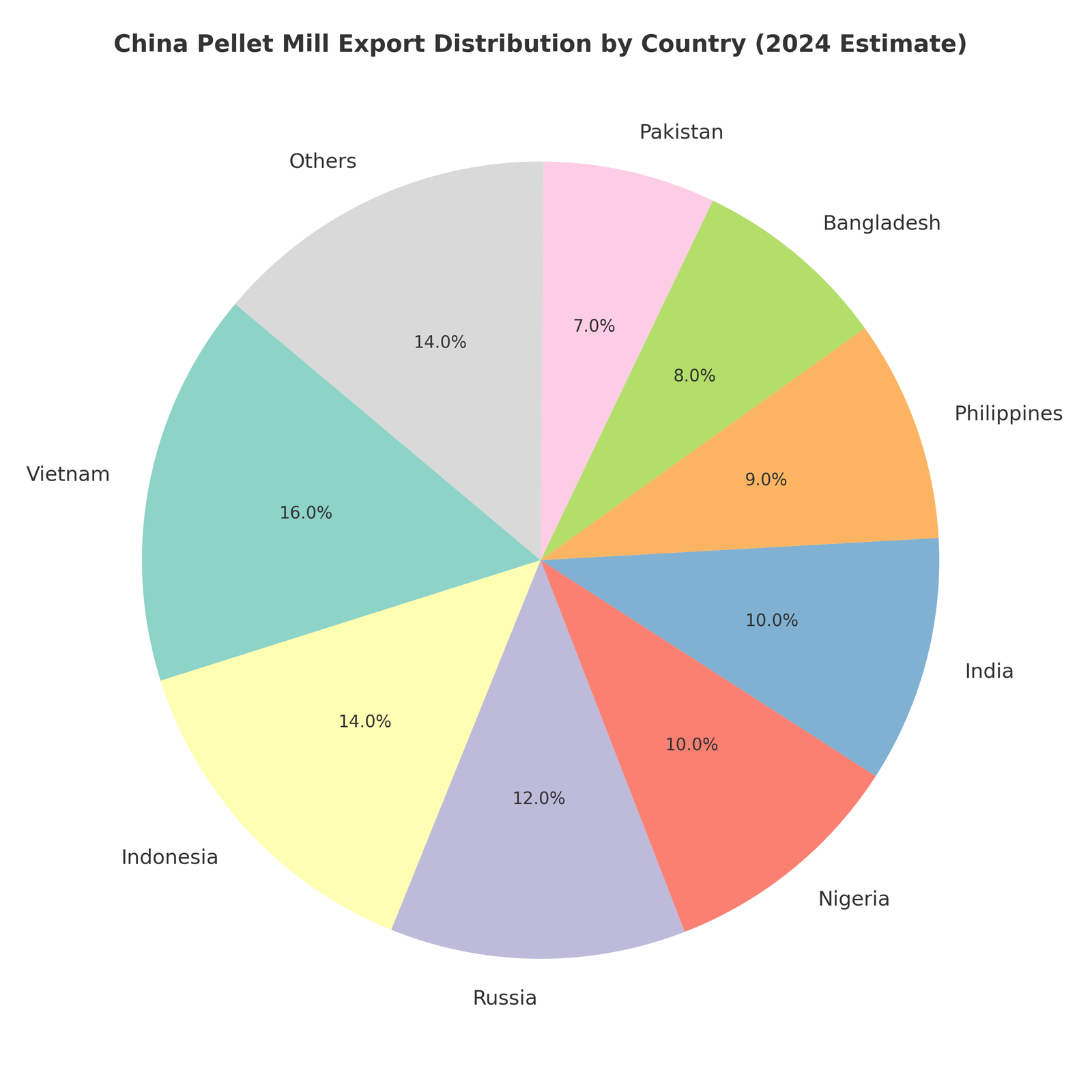

For regions such as Southeast Asia, Africa, and parts of South America, EFB pellet projects align well with local raw material availability and energy demand.

Application Scenarios and Market Demand

EFB pellets are increasingly used across multiple sectors. Biomass power plants use them as a renewable fuel source, while factories adopt EFB pellets for steam generation and thermal energy. Some exporters also target international markets where biomass fuel demand is growing due to stricter carbon regulations.

For investors researching successful EFB pellet projects and equipment configurations, many industry references and case studies are available online. If you want to explore real-world installations and technical insights, check this site out to better understand how EFB pellet plants are deployed globally.

Key Factors When Selecting Pelletizing Equipment

Choosing the right machine directly affects production efficiency and operating costs. Buyers should evaluate:

- Pressing force and die durability

- Adaptability to fibrous raw materials like EFB

- Energy consumption per ton of pellets

- Maintenance convenience and spare part availability

A well-designed EFB pellet machine ensures stable operation even under continuous industrial workloads.

Future Outlook of EFB Pellet Production

As global demand for renewable energy continues to rise, EFB pellets are gaining recognition as a sustainable biomass solution. Governments and enterprises are increasingly supporting waste-to-energy projects, making EFB pelletizing a long-term opportunity rather than a short-term trend.

With the right equipment and process design, EFB pellet production can deliver both environmental benefits and solid financial returns. For producers seeking to modernize their biomass operations, investing in a reliable pelletizing system is a strategic step toward greener energy and higher resource efficiency.